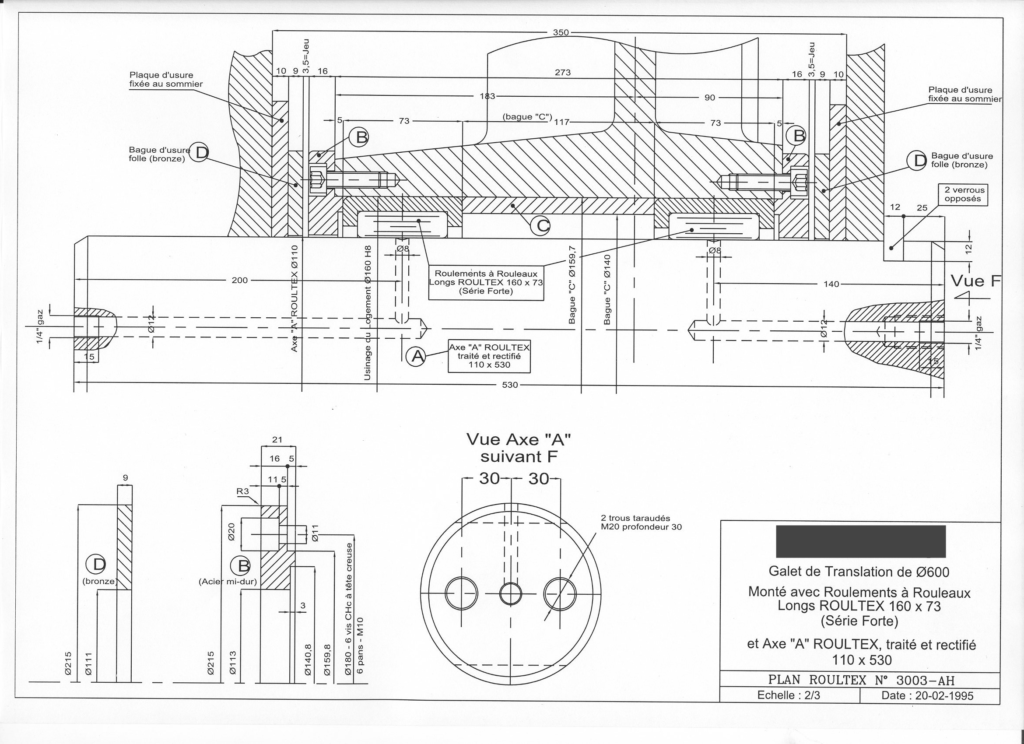

Our series for Bridge Rollers

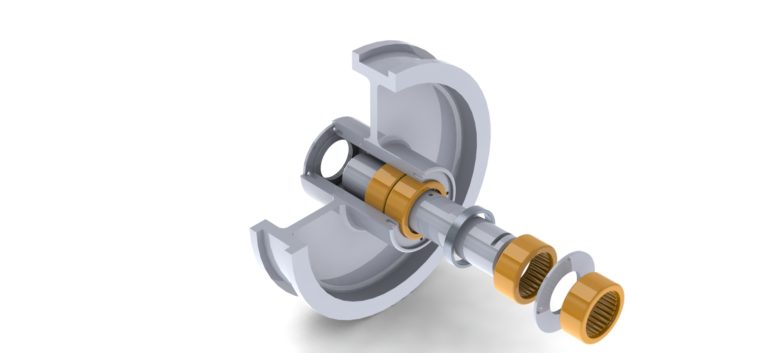

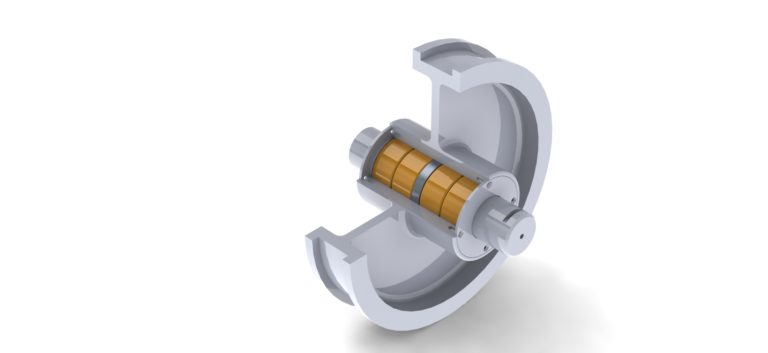

These ROULTEX® bearings are characterized by the absence of an inner ring.

They are specific to overhead cranes and are supplied with the corresponding axis.

For bridge rollers from Ø300 to Ø1000, the equipment of bridge rollers

originally equipped with bronze rings and ordinary axes.

medium series

SÉRIE MOYENNE – Rouleaux de 12×45

| AXE DE GALET | ROULEMENTS A ROULEAUX | CHARGE A60 t/m | ||

|---|---|---|---|---|

| A | B | C | D | |

| 60 | A déterminer | 102 | 61 | 4±8 |

| 70 | 112 | 61 | 5±3 | |

| 80 | 122 | 61 | 5±8 | |

| 90 | 132 | 61 | 6±3 | |

| 100 | 142 | 61 | 8±8 | |

| 110 | 152 | 61 | 7±3 | |

| 120 | 162 | 61 | 7±8 | |

Strong series

SÉRIE FORTE – Rouleaux de 15×53

| AXE DE GALET | ROULEMENTS A ROULEAUX | CHARGE A60 t/m | ||

|---|---|---|---|---|

| A | B | C | D | |

| 60 | A déterminer | 110 | 73 | 7± |

| 70 | 120 | 73 | 7±5 | |

| 80 | 130 | 73 | 8± | |

| 90 | 140 | 73 | 8±5 | |

| 100 | 150 | 73 | 9±1 | |

| 110 | 160 | 73 | 9±7 | |

| 120 | 170 | 73 | 10±4 | |

| 130 | 184 | 75 | 11±2 | |

| 140 | 195 | 75 | 12± | |

Large strong series

SÉRIE FORTE LARGE – Rouleaux de 17×62

| AXE DE GALET | ROULEMENTS A ROULEAUX | CHARGE A60 t/m | ||

|---|---|---|---|---|

| A | B | C | D | |

| 60 | A déterminer | 115 | 83 | 9±5 |

| 70 | 125 | 83 | 10± | |

| 80 | 135 | 83 | 10±5 | |

| 90 | 145 | 83 | 11± | |

| 100 | 155 | 83 | 11±6 | |

| 110 | 165 | 83 | 12±3 | |

| 120 | 175 | 83 | 13± | |

| 130 | 188 | 85 | 14± | |

| 140 | 200 | 85 | 15± | |

| 150 | 211 | 87 | 16± | |

Reinforced large series

CAGE À ROULEAUX – SÉRIE MOYENNE

| N° |

Alésage en mm |

Ø extér. en mm |

Largeur en pouces |

Ø extér. Bag. int. En pouces |

Ø int. Bag. ext. en pouces |

Rouleaux |

Tolérances des Arbres p 6 |

Tolérances des Logements H 7 |

|||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A |

D |

L |

R |

K |

Nbr |

Ø en pouces |

|||||||

| M 180 |

100 |

180 |

3 |

1/4 |

4 |

3/4 |

6 |

1/4 |

18 |

|

3/4 |

100 |

180 |

| M 200 |

110 |

200 |

3 |

1/2 |

5 |

1/4 |

7 |

|

16 |

|

7/8 |

110 |

200 |

| M 215 |

120 |

215 |

3 |

7/8 |

5 |

5/8 |

7 |

1/2 |

18 |

|

15/16 |

120 |

215 |

| M 230 |

130 |

230 |

4 |

1/4 |

6 |

1/16 |

8 |

1/16 |

18 |

1 |

|

130 |

230 |

| RM 215 |

130 |

215 |

4 |

7/8 |

6 |

|

7 |

1/2 |

20 |

|

3/4 |

130 |

215 |

| M 250 |

140 |

250 |

4 |

3/4 |

6 |

5/8 |

8 |

3/4 |

18 |

1 |

1/16 |

140 |

250 |

| M 270 |

150 |

270 |

4 |

3/4 |

7 |

1/16 |

9 |

7/16 |

18 |

1 |

3/16 |

150 |

270 |

| M 290 |

160 |

290 |

4 |

7/8 |

7 |

5/8 |

10 |

1/8 |

18 |

1 |

1/4 |

160 |

290 |

| M 310 |

170 |

310 |

5 |

3/8 |

8 |

1/16 |

10 |

13/16 |

18 |

1 |

3/8 |

170 |

310 |

| M 320 |

180 |

320 |

5 |

7/8 |

8 |

15/32 |

11 |

7/32 |

19 |

1 |

3/8 |

180 |

320 |

| M 340 |

200 |

340 |

6 |

7/8 |

9 |

1/14 |

12 |

|

20 |

1 |

3/8 |

200 |

340 |

| M 380 |

220 |

380 |

6 |

7/8 |

10 |

7/16 |

13 |

3/16 |

22 |

1 |

3/8 |

220 |

380 |

—–

| N° |

Charges admises en LBS (1 LB = 453 g) suivant nombre de t/mn |

|||||

|---|---|---|---|---|---|---|

| 50 |

100 |

200 |

300 |

500 |

1000 |

|

| M 180 |

31 100 |

23 500 |

17 000 |

13 550 |

9 640 |

5 680 |

| M 200 |

38 000 |

29 000 |

20 500 |

16 300 |

11 800 |

5 730 |

| M 215 |

43 700 |

33 200 |

23 700 |

18 700 |

13 400 |

7 800 |

| M 230 |

54 800 |

41 400 |

29 400 |

22 400 |

15 900 |

8 900 |

| RM 215 |

59 000 |

44 200 |

30 400 |

23 900 |

17 200 |

9 400 |

| M 250 |

60 900 |

49 600 |

3 500 |

26 300 |

20 000 |

14 100 |

| M 270 |

64 000 |

51 800 |

36 200 |

28 100 |

20 800 |

10 600 |

| M 290 |

67 000 |

53 700 |

38 600 |

30 400 |

21 300 |

11 200 |

| M 310 |

72 800 |

63 400 |

48 400 |

35 900 |

26 100 |

13 500 |

| M 320 |

75 000 |

72 900 |

55 300 |

44 000 |

30 200 |

15 300 |

| M 340 |

113 000 |

95 000 |

69 100 |

53 600 |

34 600 |

17 800 |

| M 380 |

122 000 |

100 500 |

72 400 |

56 500 |

|

|

Table giving the loads at 50 rpm for a duration of 5000 hours.

At other speeds these loads must be multiplied by the following coefficients:

Rounds per minute | 30 | 60 | 120 | 260 |

|---|---|---|---|---|

| Coefficient | 1.25 | 1 | 0.8 | 0.6 |

For other durations, these loads should be divided by the following coefficients:

Operating time | 5000 | 15000 | 25000 | Heures |

|---|---|---|---|---|

Duration coefficient | 1 | 1.5 | 2 |

The loads shown in the table are intended for bearings operating with shocks